Canadian Advanced ESP Inc. manufactures a wide range of ESP for artificial lift and other specialized applications.

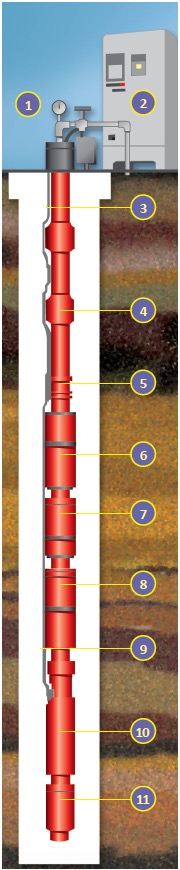

The CAESP Electric Submersible Pump System consists of several components that are carefully selected to create the most economical and efficient solution for each set of well conditions.

Wellhead (1) The wellhead provides structural and pressure containing interface for the drilling and production equipment.

Surface Equipment (2) Above ground a system controller combined with a Variable Frequency Drive and related transformer or the patented CAESP Variable Frequency Generator provide controlled power supply to the ESP.

Power Cable (3) Motor Lead Extension (9) The electrical main cable and the flat cable motor lead extension with pothead connect to the surface equipment with the ESP motor and well monitoring device.

Drain Valve (4) Check Valve (5) Other protective devices are located above the pump discharge. These include the check valve that closes on backflow and prevents back spinning and the drain valve that allows for pulling the ESP without a wet tubing string.

Pump (6) The pumping unit itself consists of the multi-stage centrifugal pump housed in a pressure sleeve with the capability of producing capacities up to 100,000 BPD (16,000 m3/d) from depths of up to 15,000 ft (4,575 m).

Intake/Gas Separator/Gas Kompressor (7) Immediately below the pump is the intake combined with a gas separator if required. The gas separator allows for trouble free operation in well conditions with free gas contents of more than 10% to 20%. The CAESP Gas Kompressor can handle up to 45% of free gas.

Protector (8) Located between the motor and pump intake is the protector. The protector isolates the motor from the well fluid and contains the high capacity thrust bearing.

Motor (10) The high quality electrical motor for well casings 4-1/2” (114 mm) and larger is a squirrel cage, two pole, three phase induction motor. The motor turns at a speed of approximately 3,500 RPM at 60 HZ and 2,900 RPM at 50 HZ.

Sensor (11) The down hole sensor is located below the motor and transmits important well and system data via the main power cable to the surface.

Expert Advice The correct application of technology is the critical success factor for any down hole pumping solution. You can count on Canadian Advanced ESP’s professional engineers to design an Electric Submersible Pumping System that provides optimum performance in each of your well applications.