The HPS system is a range of multi-stage centrifugal pumps.

The HPS system from Canadian Advanced ESP Inc. features high pressures and medium flow rate characteristics, which are a reliable and economical choice for a wide range of oilfield, mining, and industrial applications.

Canadian Advanced ESP Inc. is the only HPS manufacturer that designs, builds and tests all of its equipment in Canada, in their ISO 9001:2008 certified facilities located in Edmonton, Alberta. Standard product capabilities include discharge pressures of up to 4800 psi (33.0 MPa) and flow rates up to 1700 USGPM (385 m3/hour).

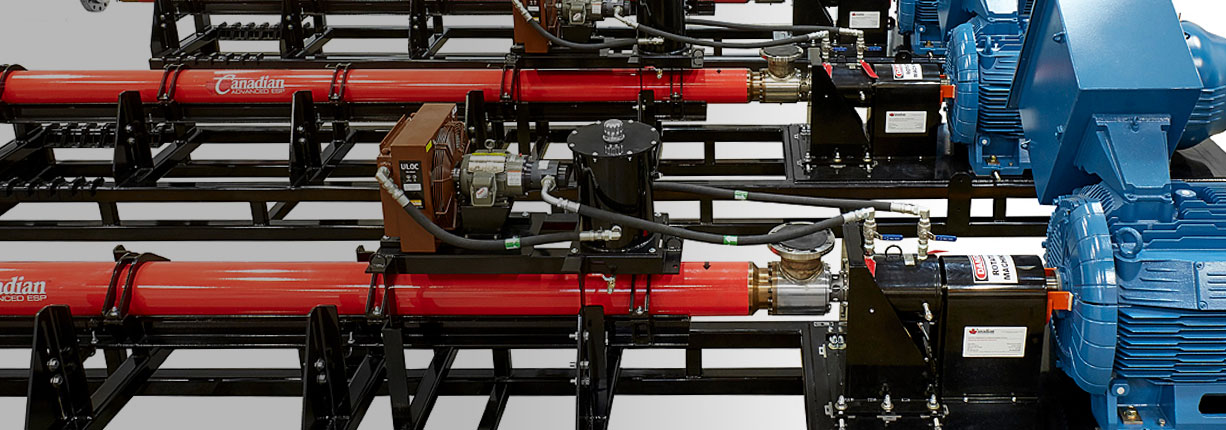

An HPS unit typically consists of a horizontally-mounted multi-stage centrifugal pump, prime mover (electric motor or optional gas/diesel engine), thrust chamber, intake manifold, and discharge, all mounted on a heavy-duty welded I-beam skid.

Standard pump materials of construction include Ni-resist impellers and diffuser bowls, Monel(R) shafts, tungsten-carbide bearings, carbon steel diffuser housings, Viton(R) elastomers, and stainless steel intake manifold and discharge flanges. Other materials and construction options are available to meet more demanding fluid handling requirements.

Over the past twenty years, the HPS-style pump has proven to be a cost-effective alternative to split case, vertical turbine, and positive displacement pump designs in many applications. When compared to these conventional pump types, the HPS system offers high reliability, flexibility, timely delivery, and minimal maintenance.

HPS units have proven successful in applications as diverse as:

- Oilfield water disposal and waterflood pressure maintenance

- Crude oil transfer and pressure boosting

- Liquid propane transfer

- Dense-phase liquid CO2 pumping

- Power fluid pressurization for subsurface jet and piston pumps

- Amine circulation systems

- Mine dewatering

Canadian Advanced HPS units are provided as a complete system from a single-source vendor and delivered preassembled to the site. The modular design provides for easy maintenance, and minimizes downtime when maintenance is required. All major components can be exchanged within two to three hours and, with the exception of the motor, do not require re-alignment before the pump is restarted.